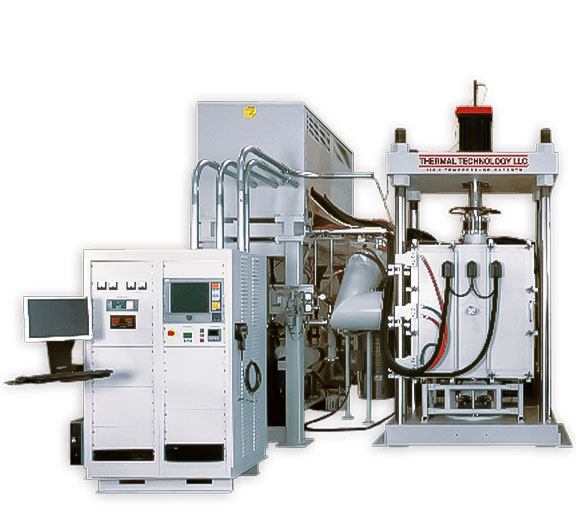

Hot Press Furnace systems (HP) allow for the precise application of hydraulic pressing force and simultaneous high temperature operation. Typical uses for hot press include sintering of metal or ceramic powders and diffusion bonding of solid components. The furnace systems are comparable to our High Temperature Graphite, Hydrogen Furnaces, and Advanced Processing Furnace product lines, with a range of hot zone materials available. All HP systems utilize state of the art hydraulics for extremely high precision force and/or position control. Automatic operation is conducted by PLC based control utilizing a touch screen HMI. Automatic hydraulic safety systems limit force application while the furnace chamber is open to mitigate die breakage and operator injury, in addition, two-hand operation is required for all manual motion control to prevent pinch hazards.

Standard hot press furnace sizes are available up to 2,000 kN (204 Ton), larger units are available and are custom built to the specific application, please contact us for details.

Standard Hot Press Furnace Product Features

- Maximum Pressing Temperature: 2,500°C

- Vacuum (10^-3 Torr range) and Inert gas (Ar, He, N2) operation.

- Fully automatic operation by PLC and touchscreen HMI.

- Simultaneous temperature and pressure control.

- Thermocouple and Pyrometer based temperature control.

- Rapid vacuum cycling: typical <10min

- Water flow and furnace overtemperature system protection

Common Optional Upgrades

- Increased throughput vacuum pump

- High vacuum pumps (Diffusion, Turbo, Cryo)

- Glovebox integration for reactive or hazardous materials

- Gas quenching systems for rapid cooling

- Combustible gas safety system (Hydrogen, Methane, ect.)

Hot Press Furnace Product Examples

Standard Vacuum Hot Press Models

| Model Number | Force kN (Tons) | Working Diameter mm (Inch) |

|---|---|---|

| HP 10 | 100kN (10.3 Ton) | Ø 75 (3) |

| HP 25 | 250kN (25.5 Ton) | Ø 150 (6) |

| HP 50 | 500kN (51 Ton) | Ø 200 (8) |

| HP 100 | 1,000kN (102 Ton) | Ø 300 (12) |

| HP 200 | 2,000kN (204 Ton) | Ø 600 (24) |

| HP 500 | 5,000kN (510.2 Ton) | Ø 914 (36) |

| HP 800 | 8,000kN (815.8 Ton) | Ø 914 (36) |

Larger Models Available. Contact for Details.

Download Product Brochure

View Brochure

View Brochure