As the first US OEM for Spark Plasma Sintering (SPS)/Direct Current Sintering (DCS) press furnace systems, Thermal Technology LLC has advanced this rapid processing technology to its furthest possibilities for lab and commercial scale use. Applications include metals, ceramics, composites, and diffusion bonding. These product lines are Top Tier systems which span from 5 to 800 tons and beyond.

What is Spark Plasma Sintering

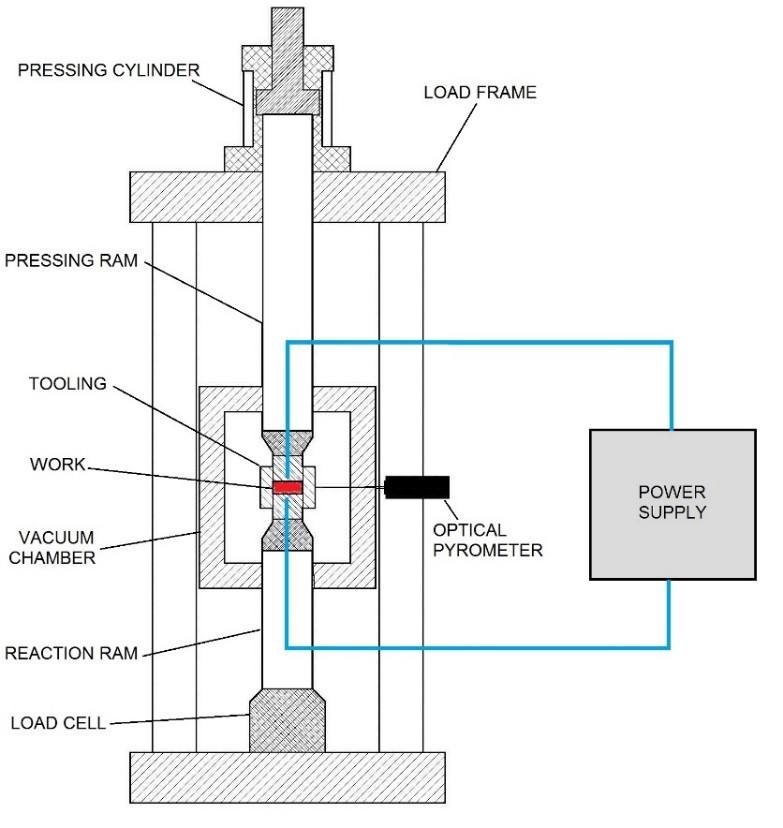

The Direct Current Sintering furnace is Thermal Technology’s product offering for the process known as Spark Plasma Sintering (SPS) or the Field Assisted Sintering Technique (FAST). The process uses high electrical current to rapidly heat a conductive tooling assembly under simultaneous uniaxial pressure inside of a vacuum chamber. With no heating elements extremely rapid heating and cooling of the sample is possible, enabling high density materials to be sintered with ultra-fine or even nano-sized grain structures. The rapid precisely controlled high temperature coupled with high applied force in the sintering process creates a high density material needed for special applications not obtainable with other processes.

Our Direct Current Sintering furnaces are used in both research and development as well as industry of specialized materials. They can be found in national labs and universities to manufacturers around the world on the cutting edge of their industry.

The Process

All Direct Current Sintering furnaces feature state of the art compact power supplies to deliver the high currents required for rapid heating. Our standard units have a maximum temperature of 2,500°C. Laboratory units (DCS 10 and 25) are equipped with pulsed and continuous DC power capabilities as standard. Larger industrial units operate with continuous DC as standard and pulsed DC available as an option. All systems feature an easy to use touchscreen interface and state of the art hydraulic controls for fully automatic operation.

The sintering system is also upgradeable with a variety of options, including; gas-quenching for rapid cooling, glovebox integration for hazardous materials, and high-vacuum pumps. Our sales team can answer any questions and help you determine the right system for your specific application. Send us an inquiry to be connected with an appropriate sales team member

The DCS process allows rapid heating of materials with applied pressure within a conductive die assembly that is processed within a vacuum chamber.

Standard DCS Product Features

- Maximum temperature: 2,500°C (limited by part size).

- Vacuum (10^-3 Torr range) and Inert gas (Ar, He, N2) operation.

- 10 Volts for heating power (Higher voltages available).

- Fully automatic operation by PLC and touchscreen HMI.

- Programmable heating rates to 1,000°C or higher.

- Thermocouple and Pyrometer based temperature control.

- On the fly switching between current and temperature control.

- Rapid vacuum cycling: typical <10min

- Water flow and pressing ram overtemperature system protection

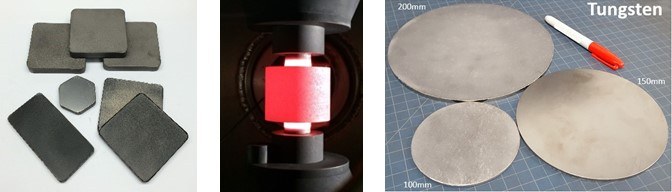

Direct Current Sintering Furnace Product Examples

Standard Direct Current Sintering Furnace Equipment

| Model | Force kN (Tons) | Heating Current | Typical Part Size mm (inch) |

| DCS 10 | 100kN (10.2T) | 5,000A* | 10-50mm (0.4-2″) |

| DCS 25 | 250kN (25.4T) | 10,000A* | 10-100mm (0.4-4″) |

| DCS 50 | 500kN (51T) | 20,000A | 30-150mm (1.5-6″) |

| DCS 100 | 1,000kN (102T) | 30,000A | 50-200mm (2-8″) |

| DCS 200 | 2,000kN (204T) | 50,000A | 50-300mm (2-12″) |

| DCS 500 | 5,000kN (510.2 Ton) | 150,000A | 100mm-560mm (4”-22”) |

| DCS 800 | 8,000kN (815.8 Ton) | 150,000A | 100mm-560mm (4”-22”) |

*Pulse DC capable power supply standard.

Note: Maximum part size will be dependent on target temperature. Inquire within for more details.

Larger Models Available. Contact for Details.

Standard Product Features

- Maximum Pressing Temperature: 2,500°C

- Vacuum (10^-3 Torr range) and Inert gas (Ar, He, N2) operation.

- Fully automatic operation by PLC and touchscreen HMI.

- Simultaneous temperature and pressure control.

- Thermocouple and Pyrometer based temperature control.

- Rapid vacuum cycling: typical <10min

- Water flow and furnace overtemperature system protection

Common Optional Upgrades

- Increased throughput vacuum pump

- High vacuum pumps (Diffusion, Turbo, Cryo)

- Glovebox integration for reactive or hazardous materials

- Gas quenching systems for rapid cooling

- Combustible gas safety system (Hydrogen, Methane, ect.)

Download Product Brochure

View Brochure

View Brochure